|

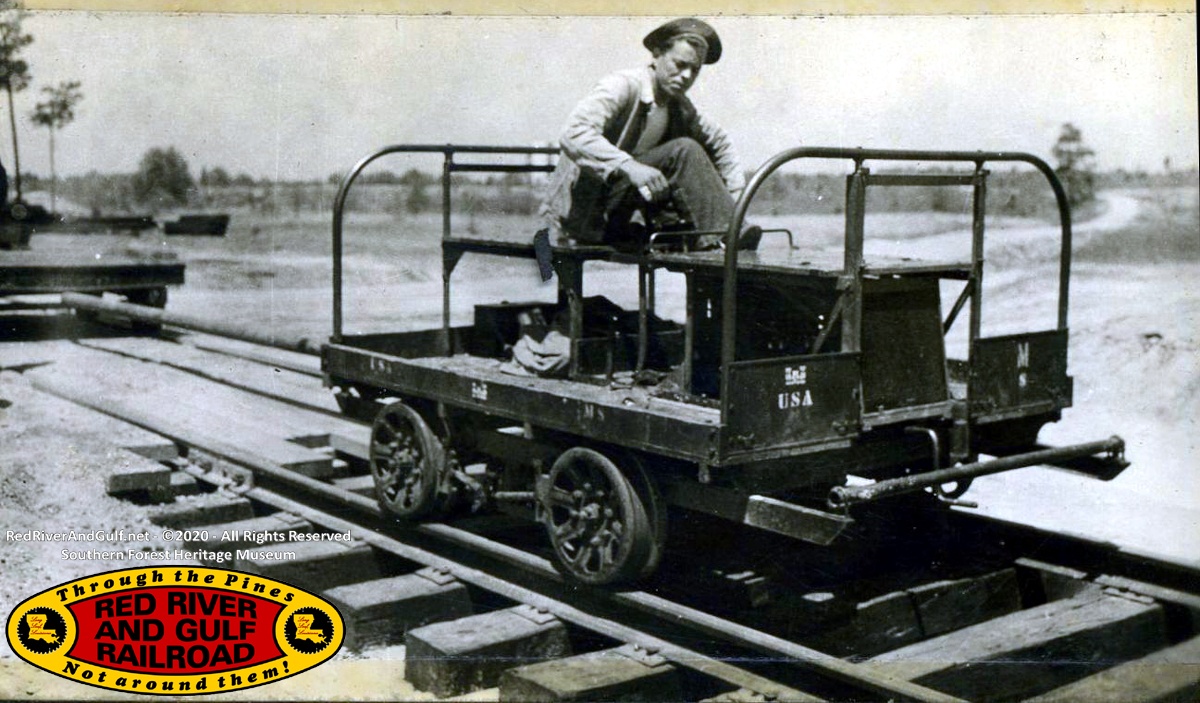

Restoring an

important part of Central Louisiana from WW-II, a 1930’s

Fairmont A-5 Rail Car “Speeder” similar to the one shown here

which was used by the 711th Railroad Operating

Battalion, part of the Claiborne-Polk Military Railroad at Camp

Claiborne Military Training Base near Alexandria, LA. in the

early 1940’s. Part of the bases mission was to train military

personnel how to build and maintain rail lines during war time.

This particular Rail Car belongs to the Southern Forest Heritage

Museum at Long Leaf, La. and will be an important addition to

their great Camp Claiborne Museum exhibition.

I was

introduced to the museum by my grandson Wimbley who has a great

love for trains, old trains in particular. After becoming

involved with the museum as volunteers, Wimbley and I decided we

would volunteer to restore the Museums Fairmont A-5 Speeder.

Since my dad Wallace was a mechanic, I inherited a lot of

necessary skills which would be useful in this restoration.

The museum

staff and volunteers had previously replaced the rusting fuel

tank with a new plastic one, installed a new battery, fuel pump

and rebuilt the carburetor which proved the vintage Industrial

Waukesha engine still ran!

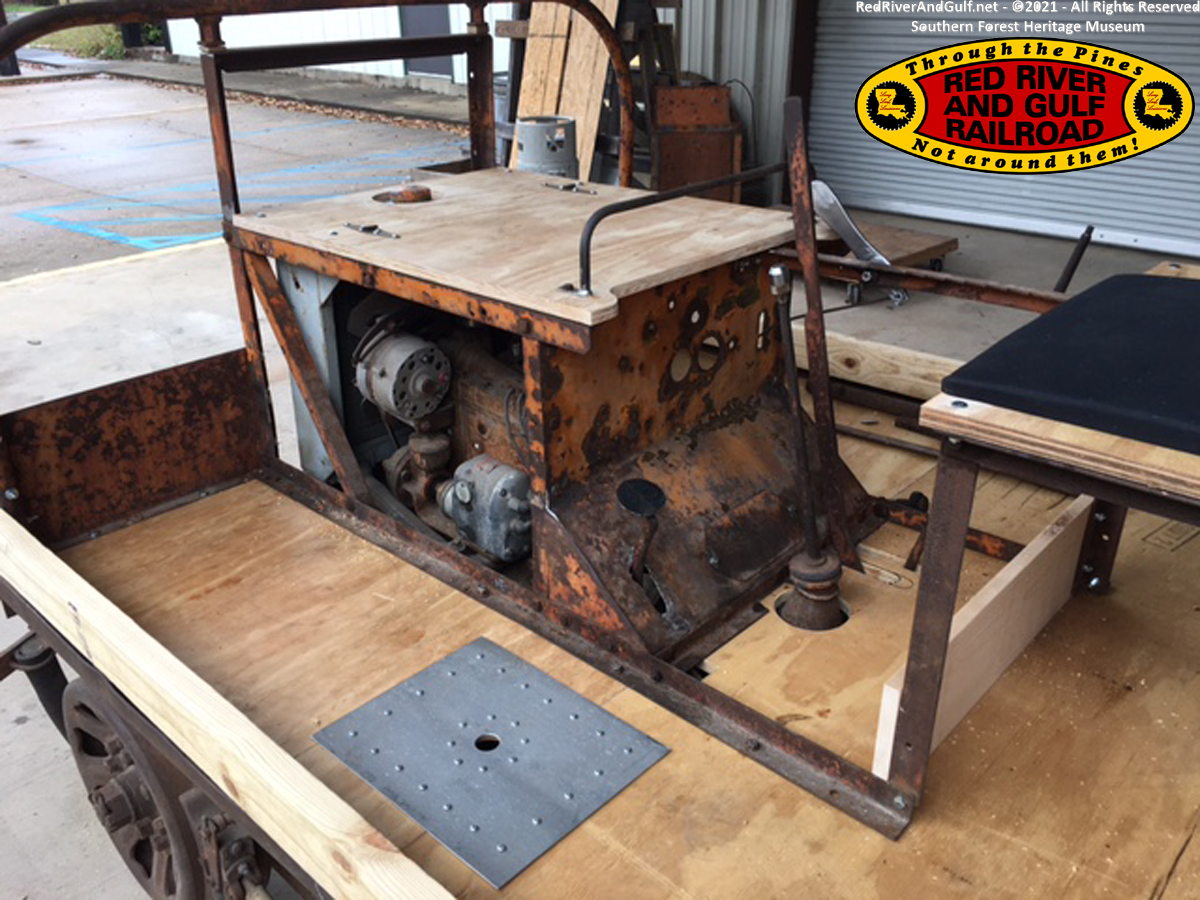

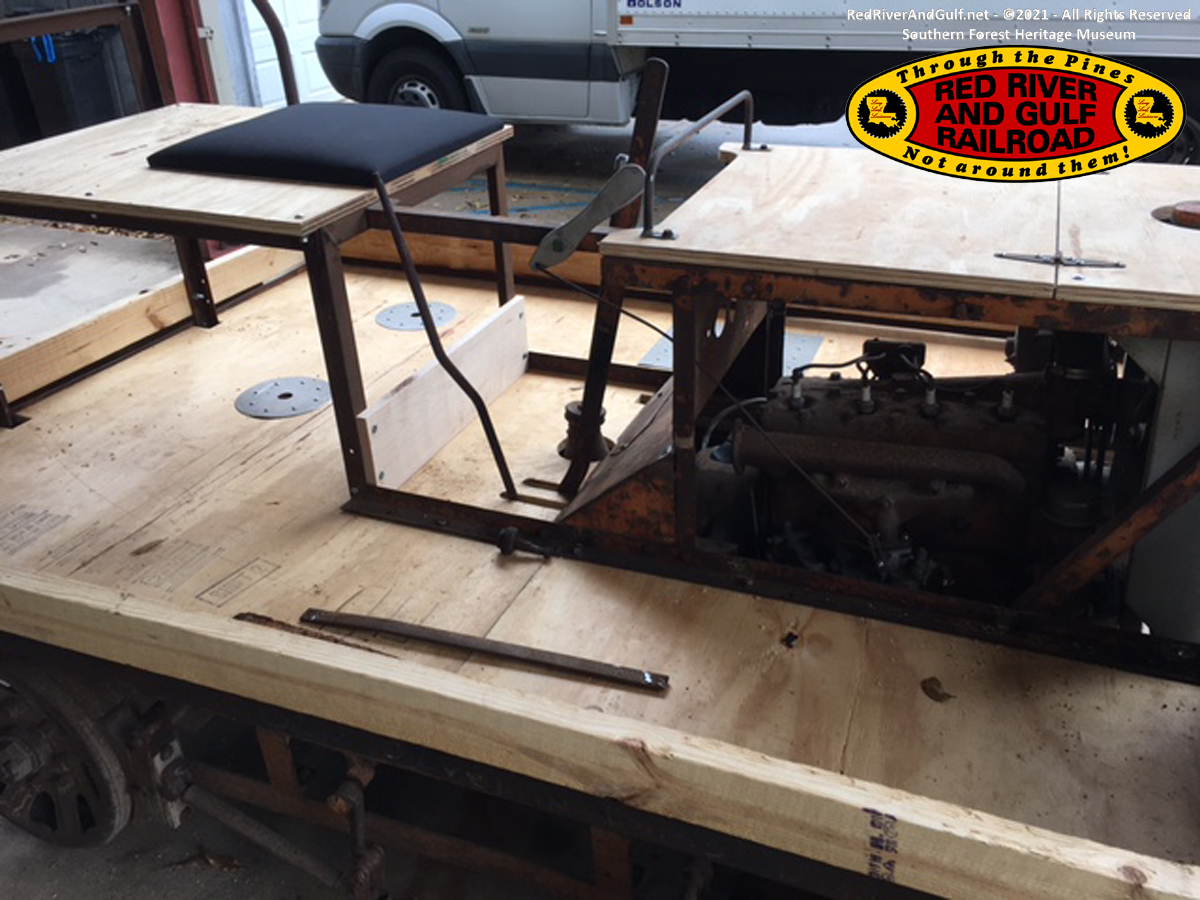

After moving

the rail car to my shop, we began by removing all the rusted and

bent metal frames, rotten wood and old wiring. Next, we repaired

all of the bent metal frames, the dash panel and removed all

parts we weren’t going to need. A new wooden floor was then

fitted to the main frame. Access holes for the battery, fuel

tank and rear end gear box were cut and removable covers

crafted. All of the modern modifications made by the previous

owner of this rail car, The Texas and New Orleans Railroad were

no longer needed and discarded. We then rebuilt the entire top

frames as shown in the inspiration photo. A thin padded seat was

added, a new throttle lever crafted, the brake handle modified

to catch the ratchet properly, and a new hinged hood and handle

were made. After we were confident all metal work on top was

correct, all was removed for cleaning and painting. The lower

main frame was pressure washed and treated with the special

chemical OSPHO for rust. During this procedure it was realized

the rubber engine mounts had settled leaving only .02 clearance

between the engine oil pan and rotating front axle. After

studying the issue, I found a way to raise the engine .35 inches

by rearranging the bushings. To accomplish this the radiator

had to be removed which dictated new coolant hoses. This

inspired us to go ahead and repaint the engine while it was

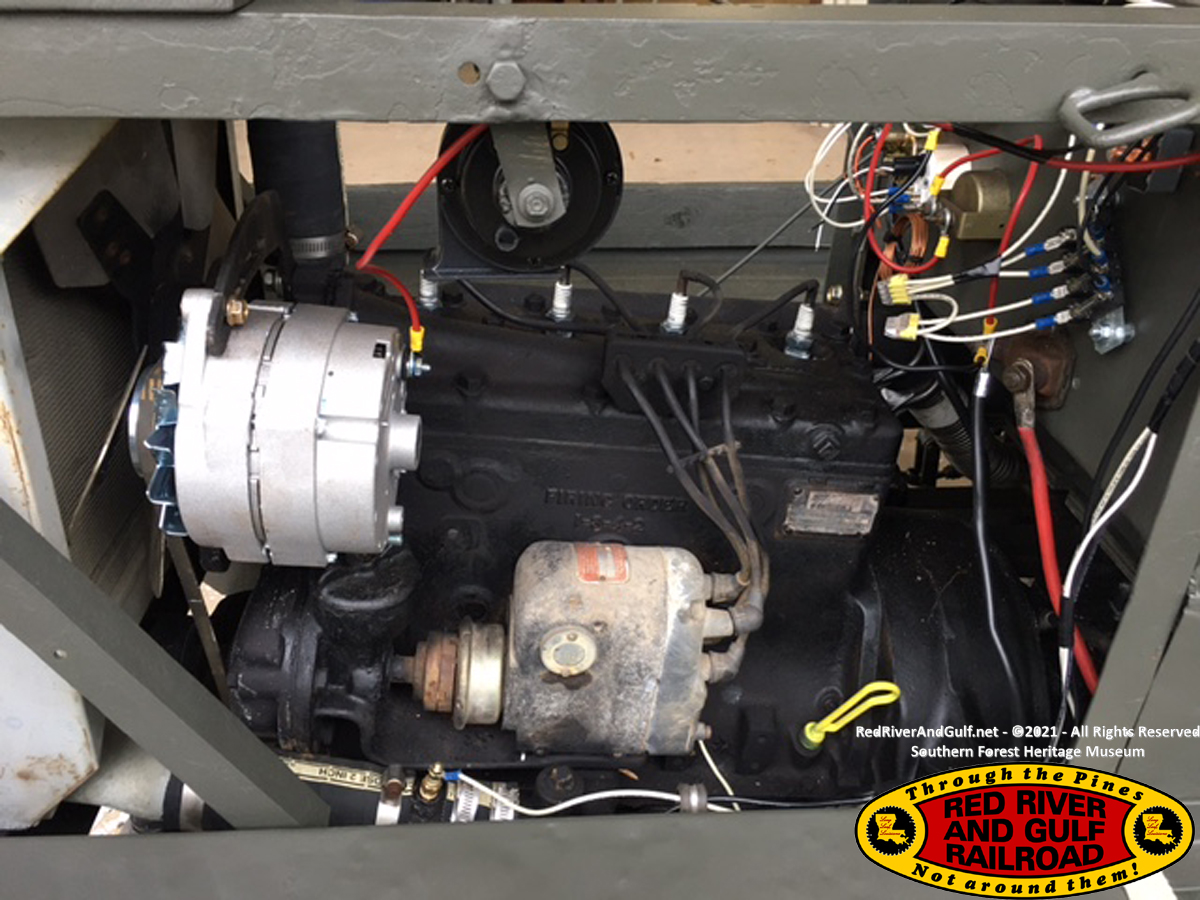

accessible. It was also deemed important to replace the

old-style alternator with a single wire type eliminating the

rectifier behind the dash panel. This also required the

alternator mounting bracket to be straightened and modified to

correct the mis-aligned drive belt. Since the iron plug suited

for the water temperature gauge probe was not able to be

removed, we crafted an inline mount for the lower hose to accept

the new temperature sending probe. A new oil pressure gauge was

procured and installed along with new spark plugs and an oil

change. The paint selected for this project was Federal

Standard Semi-Gloss Drab, “Olive Drab” for those who know

military colors.

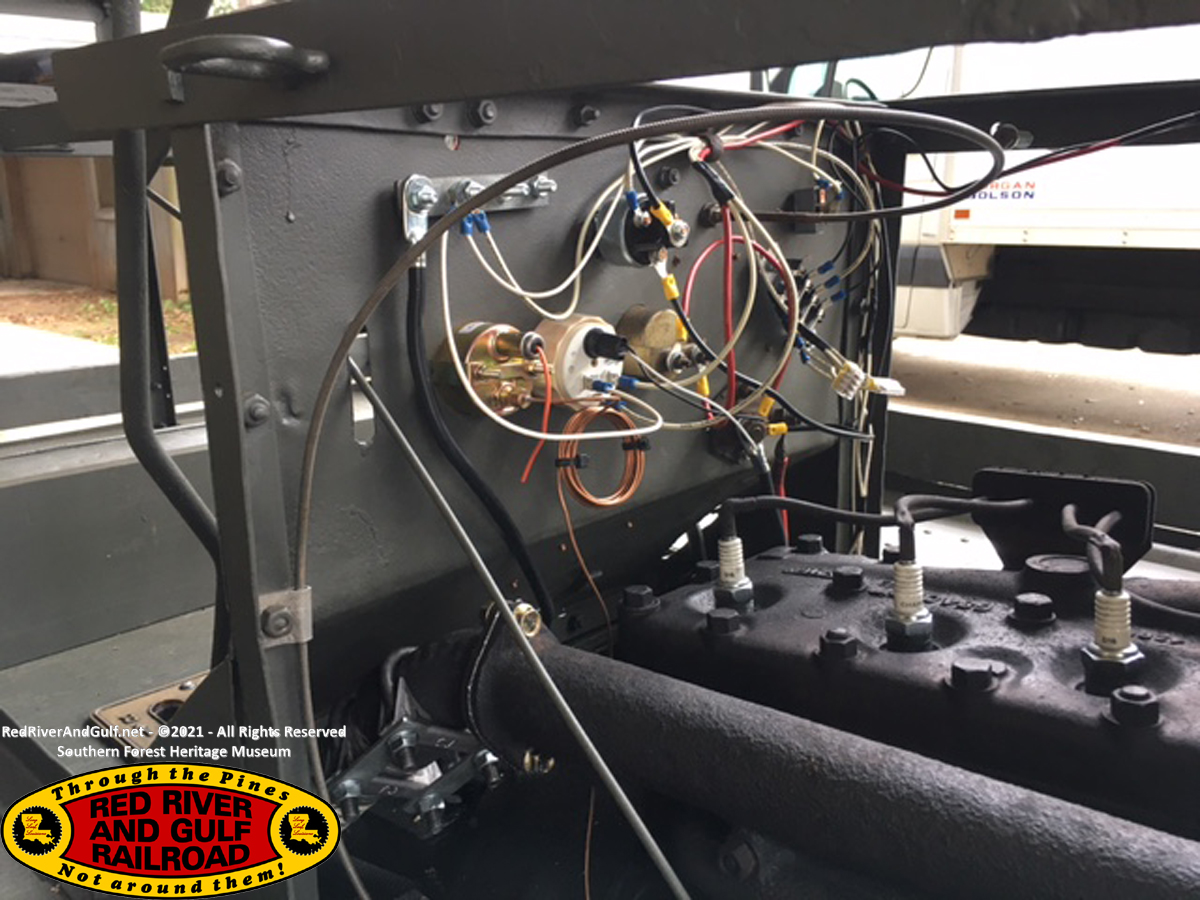

All pieces

were painted with a minimum of three coats. We then began the

process of re-assembly. When all the large parts were in place,

we began installing the smaller pieces. Eventually we made it to

the wiring. Since all the old wiring was dry rotted and

unusable, we started from scratch by installing a new fuse block

to power the new electric fuel pump, water temperature gauge,

and newly installed horn. This antique engine was fired by a

magneto, so to stop the motor you need a ground switch to ground

the magneto. A new RUN/STOP switch was added to the dash for

this. The original Master switch was also reclaimed and

installed as it should be!

There were no

placards on this rail car to indicate control assignment so we

crafted and installed new ones to indicate the switches, brake,

transmission gear pattern, travel direction, and throttle

operation.

The A-5 was

missing an air cleaner for the carburetor. With limited room to

craft and fit one under the hood we removed the old mechanical

fuel pump/filter for more room. After searching high and low for

an air filter assembly we realized it would have to be made.

With mounting space at a premium we discovered we could use a

90-degree bend 1.5” radiator hose to connect to the carburetor

throat and fit the new Honda motorcycle air filter assembly

under the right floor panel. A 1.5” flanged plumbing drain

fitting worked great to connect the air filter to the new hose!

The exhaust was next. During disassembly the flanged bend on the

exhaust manifold was punctured with a cutting wheel while

removing the old rusted bolts. This required the cut hole to be

repaired and filled. A new muffler and tail pipe were mounted

under the rear floor and connected to the manifold with a new

stainless exhaust pipe.

I think we are

ready for a test run!

-Glen Armand

|