|

Volunteer

Railroaders:

1. Chuck L.

2. Don. F

3. Mike M.

4. Mike B.

5. Everett L.

6. Jacques D.

7. Glen A.

8. Wimbley V.

9. Clint L.

10. David H.

11. Dwayne S.

12. Angela A.

13. Andrew A.

14. Kevin P.

15. Doug R.

16. Robin

17. Blake

Accomplishments

1. Naval Stores building interior

walls installation continues

2. Renovation of the kitchen in the superintendent’s house (museum

office)

3. Nuisance sycamore tree near Engine House lead track #2 removed

4. First layer of pit timbers installed and grouted in Engine House

5. Railroad bridge over Grigsby Gulch stabilized for motorcar service

6. Locomotive side rods from C&S #100 located and recovered for research

and display

7. Safety chain for museum trailer welded together

Wednesday 2/16/22 and

Thursday 2/17/22

Chuck and Don worked Wednesday and Thursday at the Naval Stores building

working on the interior walls. Part of this work includes working on the

carpentry of the corner where a tree trunk will be displayed showcasing

a sap bucket. The interior construction of the naval stores building is

close to completion and work on the exhibit space will begin soon.

Friday 2/18/22

The morning was filled with productive meetings for board members. In

the afternoon, Everett headed into Alexandria to scan historic

photographs at the Louisiana History Museum involving local railroads

and forestry. Tucker assisted Larry in moving scaffolding from the car

knocker’s shed down to the museum office, the former mill

superintendent’s house. Museum staff Robin and her husband, Blake, have

donated new flooring for the office kitchen and have undertaken repairs

and renovation to the kitchen, all on volunteer time. A leak in the roof

near an old chimney has been fixed and the new floors they installed are

an excellent upgrade. The scaffolding was needed to reach the ceiling

and the upper walls for repainting. Look inside the museum office the

next time you visit! Robin and Blake have donated both time and

materials for these improvements and we salute the museum staff on these

efforts.

At the Engine House, Glen was testing a method to lift and maneuver the

new timbers into the pit. Each 12”x12”x16’ timber weighed in at just

about 1000 pounds and placing them into the pit in the exact right spot

was quite a challenge. Glen brought his marble/granite clamp, which

could rotate, and pivot as needed, and using some high-quality plywood

and brackets, affixed a wooden “handle” on the timber. The handle was

the 1’x1’ square of plywood with bolts and brackets affixed to the

timber. This allowed the clamp, installed on the front forks of Glen’s

tractor, to grab the handle, lower the timber into the pit, remove the

clamp, and then remove the handle, leaving the timber in just the right

spot. Testing this method on Friday ensured an efficient Saturday

working with the timbers.

Later that afternoon, David Hearne came by, and with his chainsaw, a

nuisance old sycamore tree near Engine House track #2 was felled, cut

up, and moved aside. This is part of our ongoing efforts to remove

trees, brush, and vegetation near historic buildings and the historic

railroad right of way. While cleaning up and sizing up the nearby area

for further clearing efforts, David spotted what we believed to be the

end of a locomotive tender drawbar near locomotive #400. The next day

this artifact would be investigated further.

Wrapping up the afternoon, I rounded up the equipment and materials for

Saturday. A wheelbarrow, a garden hoe, an edger, a leaf shovel, and a

broom were brought up to the Engine House and staged for Saturday. Mike

Miller had already purchased the needed grout and staged the bags in the

Engine House. The museum chainsaw was checked and topped off with fuel.

Saturday 2/19/22

A full crew turned out for Saturday, and much was accomplished in many

teams. Firstly, David Hearne donated his skills to attach a safety chain

for the museum trailer, which Doug had worked tirelessly on getting

plated. Having a trailer with a license plate will be a big help in

securing donated materials for the museum, including crossties. The

trailer had eyes to attach the chains and David donated midlinks and

hooks to attach the chain without any welding. David also installed a

wiring kit to have the lights functional on the trailer. Doug reported

on Monday that the paperwork is now all to receive the license plate for

the trailer.

Crew #2 of Everett, Jacques, Angela, Dwayne, Wimbley, and Clint began

work early in the morning. The first items were moving the M4 down to

the commissary and moving out the equipment from Engine House track #1.

This track was cleared so crew #3 could begin installing the new timbers

for the pit with Glen’s tractor.

After the switching movements, crew #2 headed out with a flatcar loaded

with tools and timbers to make stabilization repairs on the bridge over

Grigsby Gulch. This bridge is located on the former Planer Mill bypass

track, which historically headed into the commissary and passenger depot

area. Today, this track forms one of the three legs of the “wye” and is

often referred to as the “switchback tracks.” In the early days of the

museum, these tracks were used to provide motorcar rides from the

commissary up to the Engine House, “switch backing” up the grade. The

footings for the bridge, originally built by Grigsby and the Reader

Railroad crew, had fallen in due to major erosion and drainage issues.

Everett had fabricated two new timber “I-beams” and these beams were

installed to provide stability for the bridge stringers. Dirt was

cleared away to access the bridge stringers and a gauge bar installed to

keep the rails in gauge. These repairs are to provide for temporary

crossing this drainage to facilitate repairs and maintenance to the

bridge and to the track on the other side.

Crew #3 of Glen, MB, Mike, Tucker, Andrew, and Kevin were at the Engine

House installing the first layer of timbers in the pit. The broom and

leaf shovel were used to give the concrete floor in the pit a thorough

cleaning. Our goal was to place the timbers as evenly and exactly as

possible to ensure as little “rocking” of the timbers as possible.

Eyelets were drilled into the timbers and rope was used to guide the

ends of the timbers down into the pit. Glen’s handle and clamp system

worked very well, and the rope guides allowed us to efficiently maneuver

the timbers into place. After the timbers were place, grout was mixed up

in several batches and the timber bottoms were grouted to ensure a

smooth, even contact with the concrete floor and to ensure no “timber

rocking.” Black vinyl was draped over the walls to provide a vapor

barrier between the treated timbers and the dirt. Mike Brown donated the

roll of black vinyl, which washed up at his house during Hurricane Ida,

and we thank him kindly for his donation. Getting the first timber right

was critical, as all the other timbers would key off this one. Multiple

measurements of where the rail would be, distance between timbers, and

timber level were taken throughout the installation process.

Right before lunch, Angela took time to show several groups on a great

tour around locomotive #400, the Engine House, the Machine Shop, and

locomotive #106.

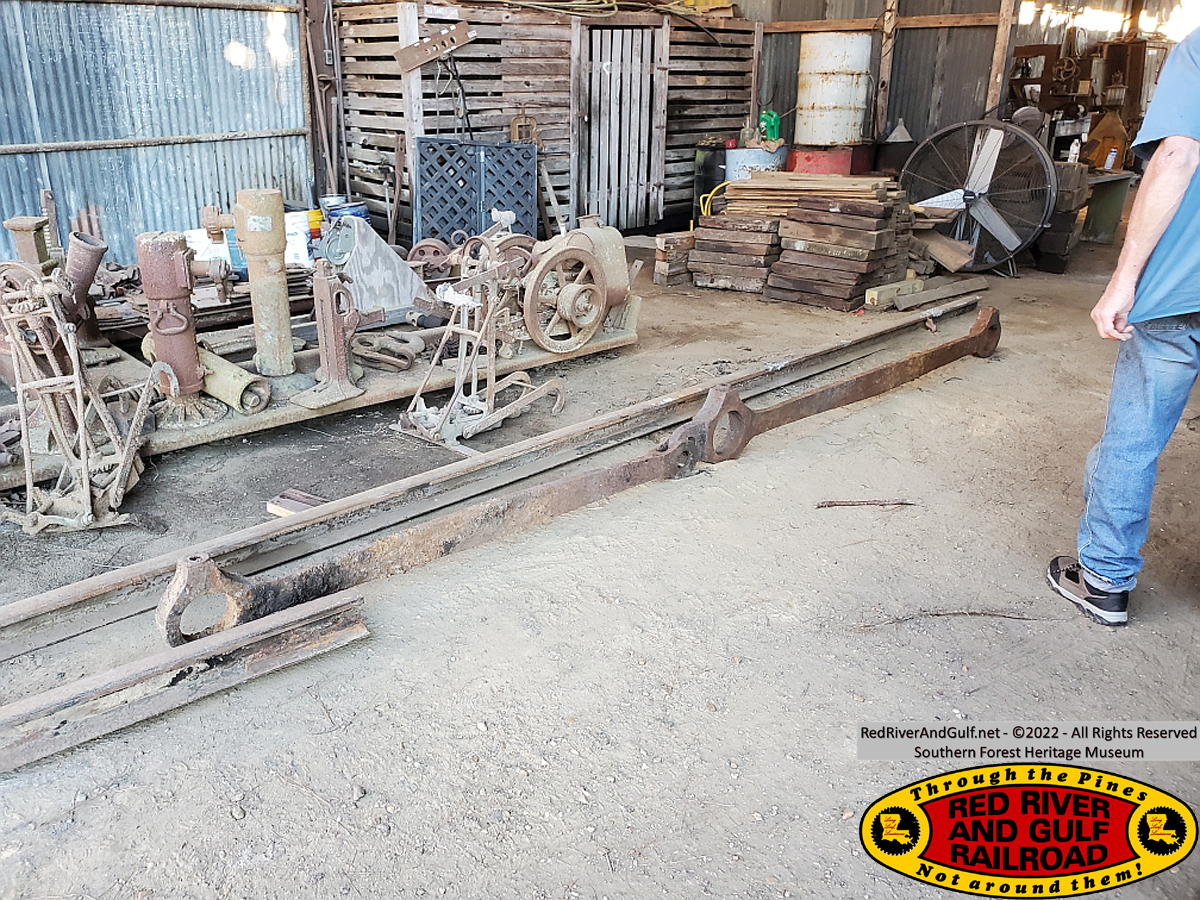

After lunch, crew #2, joined by David Hearne, Andrew, Jacques, Everett,

Dwayne, and others, used the museum tractor and chains to investigate

the drawbar we thought we came across Friday. Below is the account from

Everett: “While cleaning behind engine #400 on Friday, David Hearne and

Tucker Baker uncovered the end of what appeared to be an engine drawbar,

so after lunch on Saturday, it was decided to recover this artifact.

After some work by David and Andrew, it was suddenly discovered that

this artifact was a SIDE ROD! Not only that, but there was also a side

rod next to it as well. After recovering both rods, they were identified

as belonging to Crowell & Spencer Lima 2-6-0 #100, (Formerly Alexandria

Lumber Co. second #2 and initially Wausau Southern RR #1, Lima #1193,

built April 1912). This locomotive was used only at the Crowell

operation at Hutton, LA after being acquired from Alexandria Lumber, and

supposedly scrapped at Alco, LA about 1944-45. The discovery of this

pair of rods indicates that the locomotive actually ended up at Long

Leaf along with the other engine from Hutton, C&S #200 (which is well

documented photographically), as no one would have scrapped a

locomotive, unlike any other Crowell locomotive and taken a pair of rods

from Alco to Long Leaf. This opens up another new leaf (bad pun) in our

continuing understanding of Long Leaf History. Many thanks to Tucker,

David and Andrew!”

While the side rod recovering as ongoing, crew #3 continued work

finishing the grouting on the timbers in the pit. Doug, Glen, and Mike,

with assistance from Glen’s straps and tractor, lifted and moving the

small steam engine used for demonstrations and tours in the Engine House

into the Machine Shop. David Hamilton showed Doug the operation and

maintenance of the Engine House earlier in the month. Moving the engine

to the Machine Shop grouped this machine with other demonstration

machines in the shop and freed up much-needed space in the Engine House.

As this operation wrapped up, crew #3 was using the museum tractor haul

off the cut-up sycamore tree to the burn pile. Additionally, a

trailer-load of wood was unloaded to storage, set aside for the first

fire-up of the Heisler.

In the mid-afternoon, as the pit timber operation wrapped up, Jacques,

Angela, and Tucker began moving the M8 and trailers back into Engine

House track #1. Everett, David, Andrew, Dwayne, Clint, and Wimbley

headed out to finish up at the Grigsby Gulch bridge. Earlier in the day,

the M4 made multiple trips around the loop and the M2 with Crew #2 made

a successful trop as well. However, M2 derailed on the curve right after

the road crossing near the Engine House. Thankfully, no one was hurt. At

this point, everyone pitched in the re-right M2 and to make needed track

repairs. Using Glen’s tractor and the museum tractor, M2 was re-righted

back on the track. Upon inspection, the gauge was wide at a joint on the

curve. A quick assembly line of repairs was lined upon. As spikes were

pulled and gauge checks performed, Glen used his tractor bring in fresh

ties from the sawmill pad and used the tractor backhoe attachment to

remove the old ties. David then used the museum tractor to haul the bad

ties off to the burn pile. Seven new ties were inserted, and this

wrapped up the afternoon.

Sunday 2/20/22

On Sunday morning, volunteers were moving early. Mike Brown was working

on the big Hyster forklift. The crew of Everett, Kevin, Jacques, Andrew,

Angela, and Dwayne started work early moving out the M2, gathering the

tools, and getting ready for spiking at the new ties inserted on the

main loop. Before heading out, the brakes were adjusted on M2 to keep

them in proper working order. Within short order, the new ties were

spiked down, and this section of track was brought back to good order.

Moving to the now-stabilized bridge, the crew spiked down and secured

the ties and bridge stringers. After this, we took some time to clear

vegetation, limbs, and debris off the wye tracks and to inspect the

tender frame, wheel sets, and other historic equipment in the area.

While moving the M2 and flatcar back to the Engine House around the main

loop, the M2 derailed behind the old dry kiln. A combination of ballast

stacked against the inside rail and the gauge being tight caused the

left front wheel to climb out of gauge. Using the museum tractor,

blocks, and a lining bar, the M2 was re-righted back on the rail. The

ballast in the area was cleared out, and several sets of spikes were

reset on multiple ties in the area. The goal was to bring the whole area

into proper gauge. After these repairs, the crew returned the equipment

and tools to the Engine House and the weekend concluded.

Discussion, investigation, and reports will be completed regarding the

derailments and repairs to correct the track issues. The weekend went

mostly according to plan, and we thank everyone for their efforts and

their good attitudes the whole weekend. Many major projects are closing

to finishing this spring.

-Tucker "Who Dat" Baker

RR&G Road Master

|