|

Volunteer Railroaders

1. Jason R.

2. Everett L.

3. Mike M.

4. David H. Sr.

5. Kira S.

6. Ayden S.

7. Joseph S.

8. Gavin R.

9. Nick P.

10. Wimbley V.

11. Glen A.

12. Leo P.

13. Tucker B.

Accomplishments

1. Bar stock and plates cut & positioned for Engine House track #3

extension

2. Coupler and cut lever installed on M22 locomotive

3. Maintenance on new MOW flatcars

4. M4 rewiring completed

5. M4 ceiling insulation partially completed

6. Car clearances measured on passenger platforms and rolling stock

Thank you to everyone who volunteered this weekend. We were effective in

steady progress on our planned goals and objectives for the weekend.

Saturday

Saturday began with the morning briefing and then splitting up into

various crews. Crew #1 of Glen worked all day rewiring the M4, replacing

wire, routing the wire in better locations, and getting the ceiling

prepped for insulation and ceiling installation. This was meticulous

work, but necessary before we install the interior ceiling and walls.

The work on finishing the interior of the M4 is moving along well and

plans are underway to add an air compressor, air brakes, and sanders in

the near future. We aim to finish the M4 by the fall festival and any

resources, in-kind or financial, to help finish the project are most

welcome.

Crew #2 of Jason, David, and Joseph set to work on the bar stock

extension of the third Engine House track over the concrete pad and

under the A-frame chain hoist. Jason used the museum tractor to bring up

the bar stock to the Engine House. Everett procured the bar stock from a

supplier in Alexandria. Mike M. brought it out to the museum earlier in

the week. The crew cut ⅛ inch metal plate into “metal ties” to place on

the concrete. They then set to work welding the 1 inch bar stock to the

metal plates. After some preliminary work, they determined a bigger

welder was needed to appropriately weld the bar stock to the plates. The

plan is to finish this track at the next session later in July. This

will provide more covered track that is primarily geared for maintenance

and work on light equipment.

Crew #3 of Everett, Leo, Wimbley, and Nick set to servicing, repairing,

and initial maintenance on the newly acquired MOW cars from Port Allen.

Wimbley and Nick used M8 to bring each car over to Engine House track #3

where each car was given a thorough servicing, including oiling the

journal boxes. The wood framing on one that had been a sugarcane car was

removed, giving us a flat diamond-plate metal-deck car, ideal for MOW

use. With each car finished, the cars were placed on the car knocker

shed lead track.

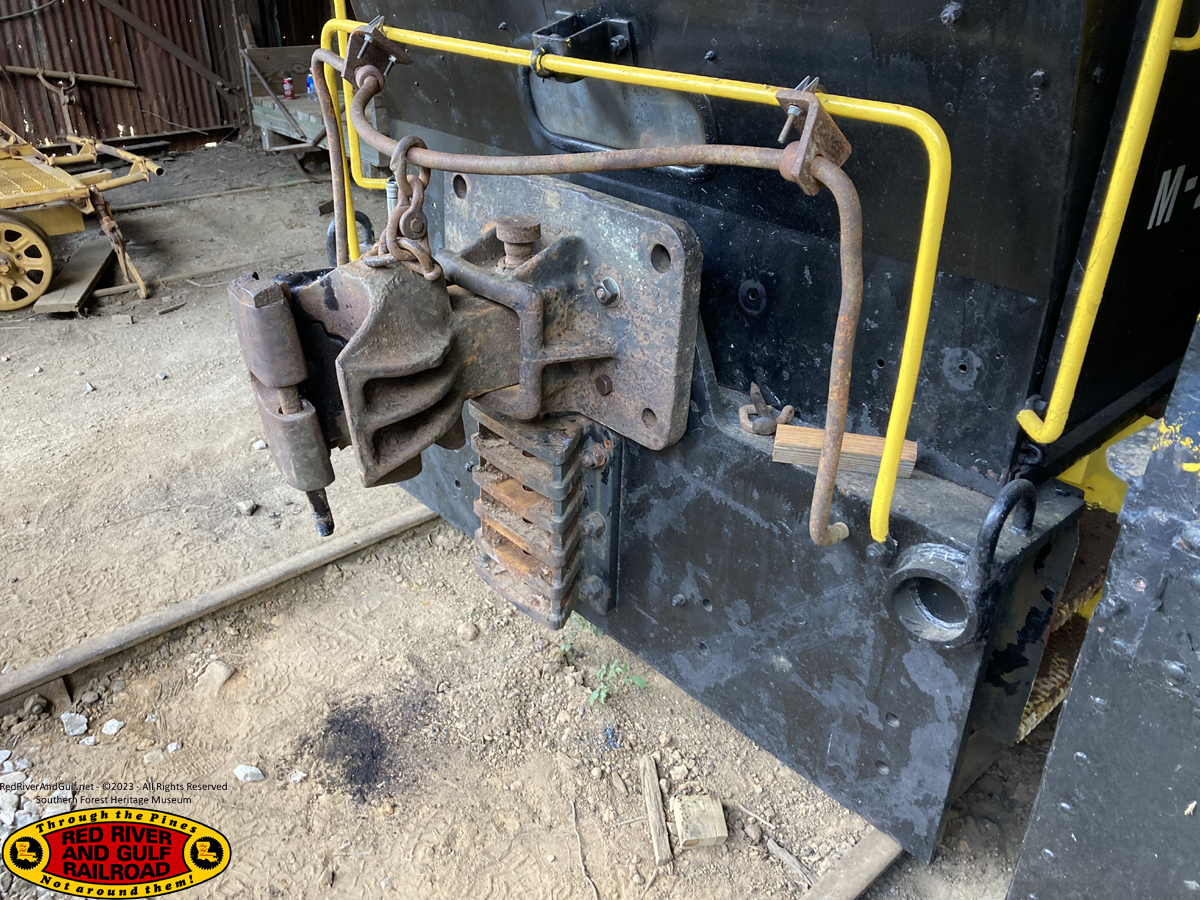

Crew #4 of Tucker, Ayden, and Gavin went hunting for the right coupler

to mount on the rear of the M22 Plymouth locomotive. After searching on

the Saw Mill pad, behind the Engine House and Machine Shop, and out in

the woods, a coupler was located at Alco locomotive #3 tender in the

woods of the wye. With much effort, the coupler was rolled and dragged

through brush up to active track, a process that took all morning.

During the morning, David, Wimbley, and Nick measured clearances for the

various steam locomotives and rolling stock compared to the passenger

platforms at the museum. The goal was to size up how much clearance work

was needed in the future at these platforms.

After lunch, all the volunteers joined up to work on the coupler for

M22. All boarded M2 and the herbicide sprayer car and headed down the

wye. After separating the coupler components, the parts were loaded up

on the herbicide car and the crew headed back to the Engine House. Back

at the Engine House, a link and pin coupler retrieved from Port Allen

was placed on the front of M22. Two of the former cane cars have link

and pin couplers, hence the use of that kind of coupler on M22.

On the rear of M22, the ¾ size coupler was removed with Gavin and Ayden

lifting it out of the way. It was too low and too small for the standard

couplers on the equipment at the museum. David and Joseph used the torch

to make new bolt holes so the alignment with the new coupler pocket and

housing would be just right. Everett and David then located bolts,

washers, and nuts from the various parts rooms around the Engine House

and Machine Shop. Using Ichabod (the crane), the new coupler pocket was

lifted and bolted to M22. The process took time, even with a bolt or two

falling into the “black hole” that was the empty space down by the air

tank, requiring effort to “fish it out.” With the coupler pocket placed,

the coupler itself was then maneuvered into place with the aid of the

crane.

With the coupler assembly placed on the rear of M22, the next step was

servicing the knuckle. Years of rust had accumulated. After heating with

the torch, some knocks with a sledge hammer, and plenty of oil, the

knuckle was completely freed up for operation. The final step was to

install a cut lever, also retrieved from Port Allen. After some

straightening of the cut lever handles, the cut lever was installed with

the addition of several links to the chain that pulls the knuckle pin.

This gave us a fully operational standard height and size coupler and

cut lever for M22. This was a needed step before moving any larger

rolling stock with M22 at the museum.

With the coupler work complete, clean up of tools and equipment was

handled, discussions were had on servicing the maintenance of way car

from Port Allen, and heading for rest after a long, hot day.

Sunday

Sunday morning, the volunteers again worked in groups. Jason and Glen

finished the last of the wiring on M4. Jason noticed that some marker

lights needed replacement, and made plans to replace & upgrade them at

the next volunteer session. David had brought another welder for use on

the bar stock track, but determined that it was not handling the job

appropriately, agreeing that a different welder would be needed. Tucker

and Ayden positioned the last of the bar stock and metal plates. Wimbley

and Nick took M8 out on the Sandersville line to remove overhanging

branches and limbs. Everett began work on the maintenance of way car

retrieved from Port Allen.

At mid-morning, Tucker and Glen started work on installing one-inch

thick insulation on the interior ceiling of M4. The insulation, cut to

size for each ceiling “compartment” was held up by plywood slats, cut to

size as well. The plywood slats would then give a good base to attach

the interior ceiling material. This was a good deal of measuring,

cutting insulation, fitting into place, cutting plywood slats, and then

screwing these slats into place. Two-thirds of the M4 ceiling was

completed on Sunday with the remainder to be finished later in the next

week.

The crew of Jason, Everett, David, Wimbley, and Nick then began work in

earnest on the maintenance of way car. This car had likely been a

Jackson tamper at some point, given the Jackson serial-number plate,

roller-bearing wheels, hydraulic tank, and gear on one axle, indicating

it was self-propelled. At some point, it had been stripped down to its

frame for conversion to a maintenance of way work flat car. For our

purposes, we plan on finishing the conversion to an all-purpose

flat-deck maintenance of way car. Numerous cuts by the torch were needed

to free the old hydraulic tank that was finally lifted free with chains

by the tractor. This too took much effort from the volunteers working on

it.

Once the MOW car was rolled back into the Engine House, Glen and Tucker

found a stopping point on the insulation work. It was a hot weekend, but

many objectives were accomplished. After dumping the Engine House

garbage cans in the dumpster and cleaning up tools and equipment, the

volunteers headed down to the lodge to clean themselves up. Kira gave

the lodge kitchen a clean as well.

The next session is July 21-23, which will include the primary session

for the Annual Rules Clinic, and continued work on the M4, M22, and

other items at the Engine House. If you cannot make the primary rules

clinic, please contact us today so secondary training dates can be set

up for you and others.

-Tucker "Who Dat" Baker

RR&G Road Master

|