|

Volunteers:

David H.

Everett L.

Dewayne S.

Clint L. Jr.

Nick P.

Joe S.

Joseph S.

Karleigh S.

Wimbley V.

Glen A.

Gavin R.

Friday

Dewayne worked welding and grinding

on the smokebox on Heisler #3. He also welded a little rise to connect

the rails on track 3 with the bar stock on the cement slab.

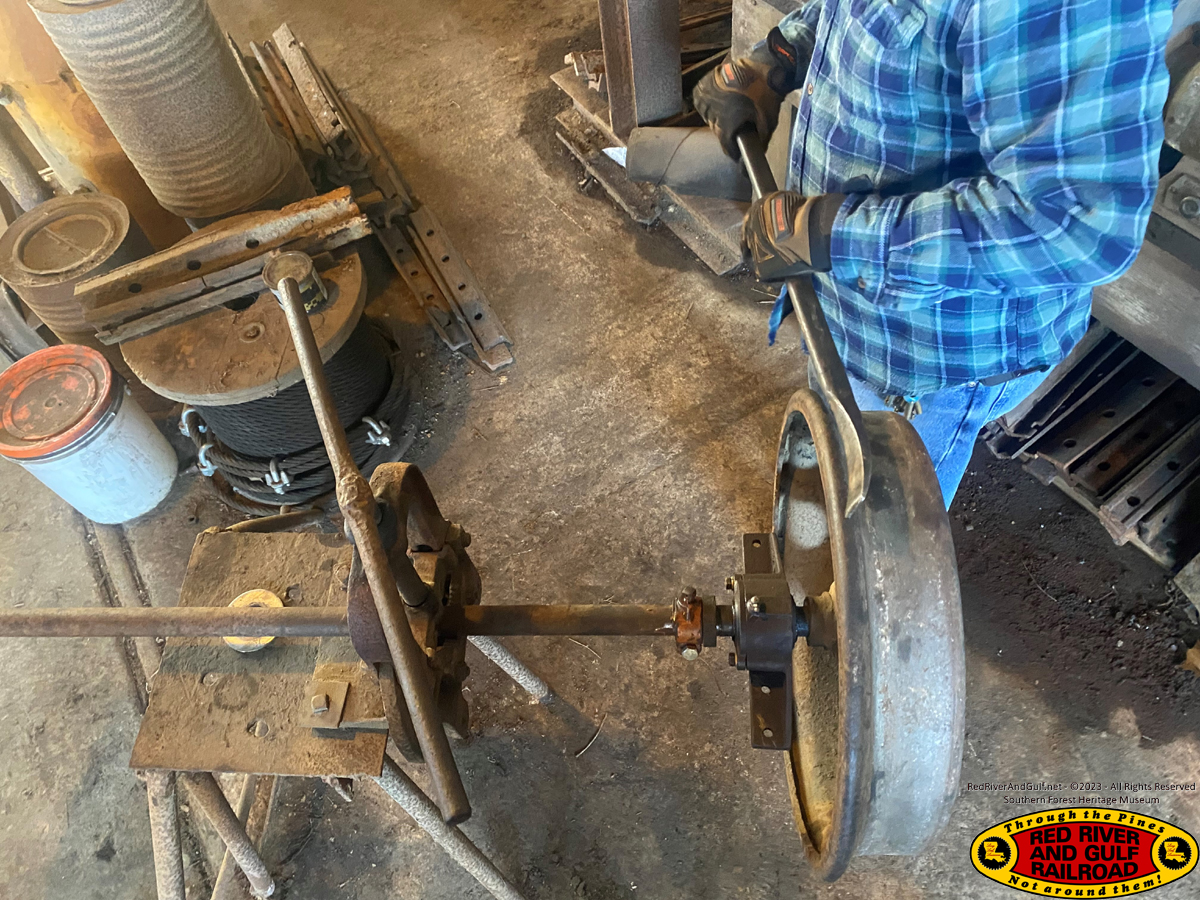

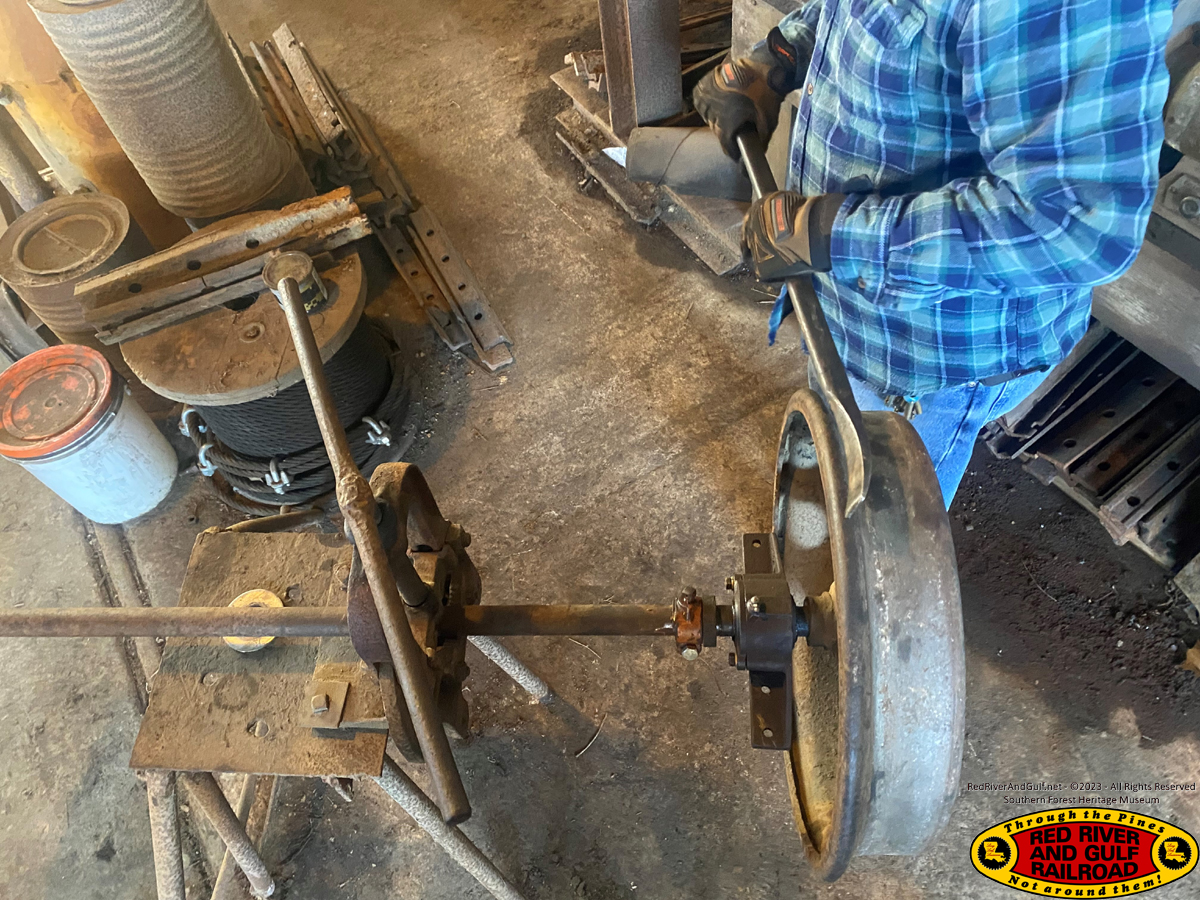

Everett gathered materials for the reconstruction of the wheels and

axles on the weed sprayer flat car,

And put together the beginnings of the first axle.

Saturday

With a full crew, the first order of

business was moving the many chain saws of different types stored in the

finished lumber shed, and the former commissary shelves that they were

stored on, out from directly under a huge leak in the roof channel that

showered a miniature Niagara Falls down directly on them and left them

standing in water after every rain. Using the all-terrain forklift,

David, Joe, Everett, Nick, Clint, Gavin and Wimbley moved the shelves

and the saws down across from the bunk house and out of the weather.

Next up, the crew went up to the Engine House where Wimbley, Clint and

Nick finished the reconstruction and rebuilding of a problem rail joint

on the loop right after the junction switch.

While Joe helped David relocate the fuel pump on the M-4 down to the

tank so that it would start better, the rest of the crew started

gathering the remainder of the materials for the rebuild of the sprayer

car.

At the last session , the crew had tackled the fire bent axles, damaged

wheels and bearings from the motor cars destroyed in the 1980 motor car

shed fire, and salvaged the wheels, axle stops and roller bearings.

During the intervening time, David H. disassembled all of the 6 salvaged

bearings, and rebuilt them to functional status, inserting grease

fittings and making them fully serviceable.

The switch crew then swapped the positions of the motor cars, and

trailers, putting the M-8 and the passenger trailer on track 1, and

bringing the sprayer car and the M-2 on to track 3 where we could use

the chain hoist to lift the car to work on the axles.

Dewayne and Gavin, meanwhile completed the welding and grinding on the

Heisler smoke box.

Then, it was time to break for lunch where a delicious chicken and

sausage gumbo awaited us at the Lodge, prepared by David’s wife Vicki.

All agreed that it was the best gumbo that any of us had eaten in a long

time! The rest of Joe’s family joined us and a great time was had by

all.

After lunch, because of the beautiful weather, most of the group went

for an exploration of the grounds to look at things that many of them

had never seen.

David and Everett went up to the engine house and began on the Sprayer

car, completing both replacement axles and removing one of the old axles

from the car. By that time the group had returned and all pitched in

finishing the replacement of that axle by the end of the work day. The

only hitch happened when one of the wheels was found to have been badly

warped by the fire and was not only warped but out of round, which

entailed much verbal discussion and extra labor to get it off of the

axle and a replacement found.

Joe went to work on the big Hyster and had much of the brake hardware

that he needed to work on removed by the end of the day.

Sunday

Sunday morning dawned crisp and cold

after the torrential rain and spectacular lighting display of Saturday

night. (Makes you appreciate being inside the Finished Lumber Shed and

out of the rain)

All hands present set to work immediately working on removing the second

axle from the sprayer car and installing the new one. It turned out to

be more difficult that the first one in that the axle bearings and stops

had been fabricated to fit the first axle to the frame, and it was

discovered that the main frame beams were not parallel. The beams are

actually 1 inch closer to each other on the sprayer end of the car, so

that all of the bearings and stops on the axles needed to be re-adjusted

accordingly.

Once the car was completed, it rolled so easily that it could be

literally pushed with a single finger

Which will make weed spraying go much faster and easier.

Most of the old friction bearings and bearing blocks were found to be in

re-useable condition should we want to make a smaller and lighter car

for them to be used on.

With the completion of the car, the group performed a general clean up

of the work area and the lodge in preparation for the month lay off

before the next session.

-Tucker "Who Dat" Baker

RR&G Road Master

|